- Continuous Sandwich Panel Production Line

- Pu Foaming Machine

- Discontinuous Sandwich Panel Production Iine

- Roll Forming Machine

- Slitting & Cut to Length Line

- CZ roll forming machine

- Sandwich Panel

- Bending Machine

Address:No.500 Qianhu Road, Huishan District, Wuxi City

Tel:0086-13771176471

Email:

manager18@wxweihua.com.cn

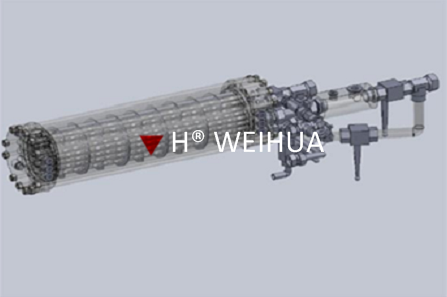

Two Components Foaming Machine

Foaming machine is the core part of the continuous sandwich panel production line. WEIHUA has now fully mastered all core technologies and successfully applied it to multiple production lines at home and abroad.

2. Technologies:

-

1) Unit pouring volume: 120—500g/s

-

2) Against-spurt pressure range of pouring injector:12-18MPa,Rated 15Mpa

-

3) Pressure adjustment of pouring injector: pneumatic, adjustable online

-

4) System control of each component flow: auto closed-loop control(suitable for manual)

-

5) Working type: continuous high-pressure operation

-

6) Volume of chemical material working tank Poly 300L ISO 300L Catalyst 150L Catalyst A 150L Catalyst B 150L Foaming agent 150L

-

7) Six-component material flow (adjustable mixing ratio) PLOY 50~300g/s ISO 50~300g/s Fire retardant 5~50g/s Catalyst A0.6~6g/s Catalyst B0.6~6g/s Foaming agent 5~50g/s. (Customer can decide on how many components they need. And foaming agent can be 141B, Pentane, etc)

-

8) Tolerance of material temperature control: ±2℃

-

9) Heating of temperature control: 6×6Kw,Cooling: 20000Kcal/h

-

10) Input power:45kw

PENTANE SYSTE

According to Montreal Protocol on Substances that Deplete the Ozone Layer published in 1989, Europe and America have ceased the use of CFC. Cyclopentane is considered as a replacement of CFC in Europe since 1993. and Now the progress to phase out CFC/HCFC is ongoing in China, India, UAE and other developing countries. For foaming system with pentane as foaming agent, the following factors need to be considered:

Cyclopentane storage system is mainly used for storing cyclopentane which is unloaded from tank truck and then feeding the material to foaming machine automatically. The design, operation and safety of the system strictly conforms to the TUV standard.

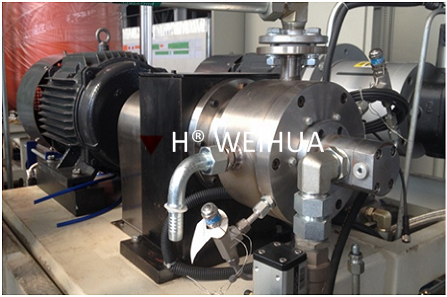

2. Pentane Foaming Machine

All pentane-related components and pipelines on the foaming machine are installed in one small room where probe and double exhaust system are equipped to ensure the security. A detection head is installed on the storage tank.

The security system is controlled by independent electrical cabinet which is separate from operation cabinet.

KEY ACCOMPLISHMENT

-

-

Five Components Foaming Machine

MORE >